Bicon SHORT® Implants

|

With Bicon SHORT® Implants you can:

|

||||

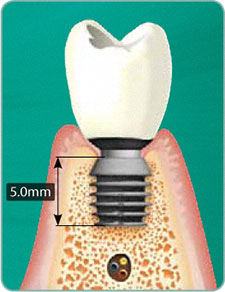

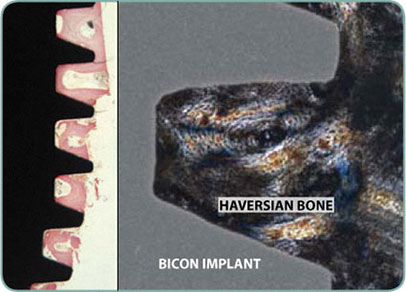

The efficacy and reliability of an implant design to biocompatibly transfer the occlusal forces on its prosthetic restoration to its surrounding bone is a significant engineering challenge. This challenge cannot be met by any single design feature such as surface area, but rather requires the appropriate integration of all of its design features. This is particularly true for short implants, because of their minimal length and higher crown to implant ratios. It is paramount that the entire design of short implants maximizes the effectiveness of each of its features within the implant’s available surface area and length. The Bicon SHORT® Implant is an example of a time proven geometric design that successfully transfers the occlusal forces on its prosthesis to its surrounding bone by appropriately integrating the following features: a bacterially-sealed, 1.5 degree locking taper abutment to implant connection and a sub-crestally placed, sloping shouldered implant with a plateaued tapered root form body. Additionally, these integrated features not only compensate for the implant’s ankylosed nature by successfully transforming occlusal forces to acceptable strains within the bone, they also provide for healthy and gingivally aesthetic peri-implant tissues, as well as for the callus formation of cortical like bone with central vascular systems. More importantly, the entirety of this design offers the patient and clinician alike the ability to place an implant in edentulous sites where there is minimal bone height, thus not only avoiding the costs and morbidity of bone grafting procedures, but also the costs of just not being able to place an implant.

|

|||||