Laboratory: Maxillary Anterior Seating Jig Fabrication

Products Needed

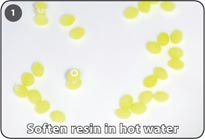

• Hot water 145°-180°F (63°-82°C)

• Hydroplastic resin (20-25 pellets/jig)

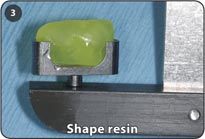

• Crown Alignment Device (260-101-315)

Fabrication of a Seating Jig

|

|

|

|

|

|

1. Add hydroplastic resin to hot water. The resin is ready to be molded when it becomes transparent (30-60 seconds).

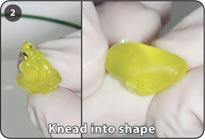

2. Remove the product and knead into desired shape.

3. Use the crown alignment device to shape the resin.

4. The incisal aspect of crown should be perpendicular to the crown seating tip.

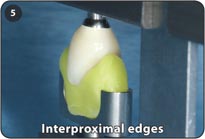

5. The resin should not cover the interproximal edges of the crown.

6. Allow jig to cool for 1 hour or submerge entire jig in cold water for 5-10 minutes.

Keys to Success:

- Do not use plastic bowls to soften the resin.

- Do not lubricate the crown prior to making the jig.